The Ford Calliope V8 Engine: A Unique Piece of Automotive History

In June 1968, HOT ROD introduced the public to Ford’s experimental big-block LeMans engine. This groundbreaking engine, developed in response to the FIA’s restrictions on engine sizes, represented a significant shift in Ford’s engineering approach. After their 1966 LeMans victory, the introduction of restrictions aimed to curb the dominance of American V-8 engines. However, Ford doubled down, undertaking an ambitious project to create a completely new engine family, distinct from their existing FE and 385-series big-blocks.

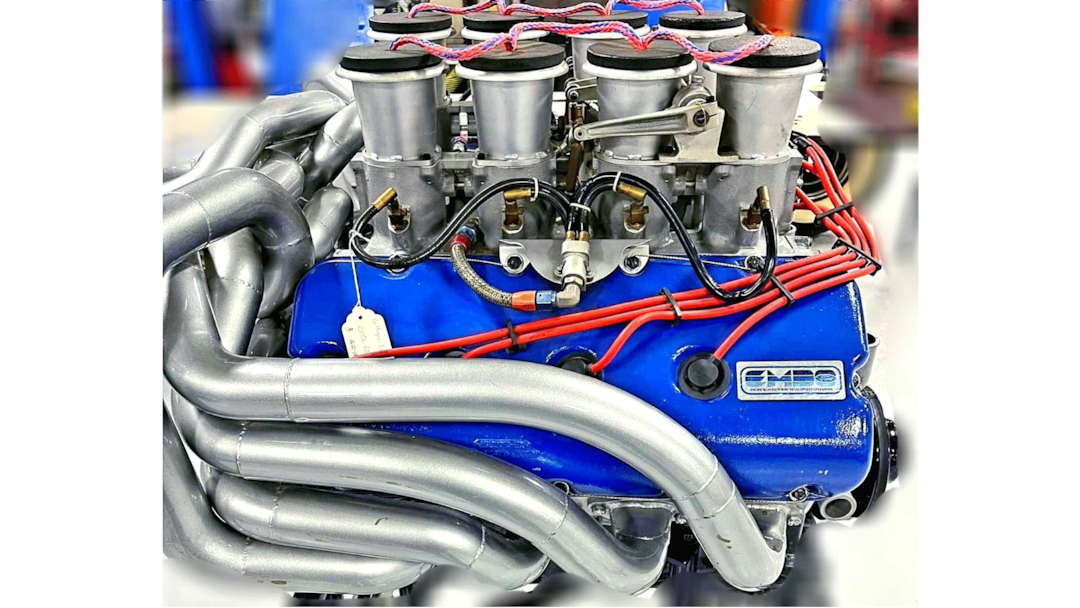

The Calliope, named after a steam-powered organ-like instrument, featured an innovative design with velocity stacks and a 180-degree header arrangement resembling a bundle of snakes. Even when the FIA regulations rendered such engines obsolete, the Calliope engine was already well under development and showed promising potential.

Ford’s progress on the Calliope V-8 was commendable, with three engines constructed and successfully dyno-tested. One of these engines was even fitted into a Can Am test vehicle, achieving an impressive output of 630 horsepower at 6,300 rpm, fueling excitement for what was to come. Ford projected that the engine could potentially reach 800 horsepower and a redline of 8,000 rpm. Unfortunately, following the HOT ROD feature, this remarkable engine largely disappeared from public knowledge, remaining dormant for years in the Henry Ford Museum.

Dan Schoneck of Schoneck Composites, an enthusiast and entrepreneur, was later granted exclusive access to the sole remaining Calliope engine for examination and documentation. As part of his undertaking, Dan aims to recreate this iconic engine, and he expressed interest in locating the other existing Calliope engines and parts.

The Calliope’s design shares its 4.90-inch bore spacing with the 385 Series “Lima” big-block, yet diverges significantly in other dimensions. With a 4.34-inch bore and a 3.60-inch stroke, the engine boasts a displacement of 426 cubic inches, commonly rounded to “427” among Ford enthusiasts. Constructed with an aluminum-alloy block housing cast-iron cylinder liners, the Calliope maintains a lightweight of just 577 pounds.

Featuring a unique three-valve, twin-camshaft arrangement, the cylinder heads are perhaps the most exciting aspect of the Calliope’s engineering. The integrated intake manifold, which runs the full length of the casting, incorporates innovative design elements, including cast bosses for mechanical fuel injection. These combustion chambers capitalize on combustion efficiencies through their fast-burn design, contributing to the overall power and performance of the engine.

Schoneck’s ambitions not only involve documenting this remarkable piece of automotive history, but he also aims to produce replicas for a select group of customers. He is currently collaborating with Jay Brown of FE Power Products to manufacture functional examples, but acknowledges that the intricate process of casting and engineering the remaining components will require significant time and effort.

As he delves deeper into the revival of this exceptional engine, Schoneck encourages anyone with information on other Calliope components to come forward. The Calliope project, though slow in its realization, symbolizes both a remarkable chapter in automotive engineering and the enduring passion of car enthusiasts dedicated to preserving historic innovations.